|

|

|

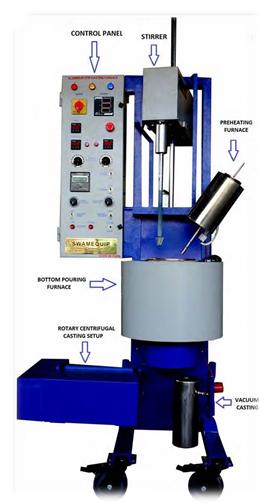

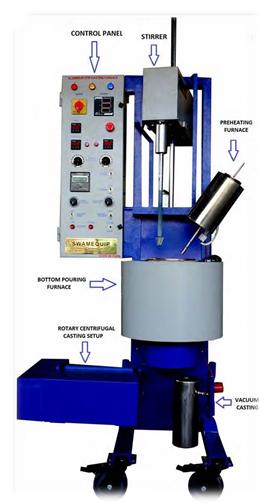

Name

of the equipment:

Computerized

Magnesium & Aluminium MMC Casting

Make

& Model:

Swam

Equip, India

I-Stem

Registration ID-

3224874

Category

of Instrument

Metallurgical

Processing Equipment

Types

of Analysis / Testing

Composite

material fabrication

Application:

Production of Aluminium/Magnesium metal

matrix composites (MMCs) by incorporating reinforcements into molten metal

Description

of Instrument

The

Bottom Pouring Stir Casting unit enables uniform mixing of reinforcements

into molten metal with controlled stirring and clean pouring from the

bottom to minimize impurities and segregation. This machine facilitates

reinforcement mixing via stir rod or ultrasonic vibration. It is also

designed to perform diverse casting methods such as gravity, vacuum,

squeeze, and centrifugal casting.

|

|

|

Book

through I-STEM:

https://www.istem.gov.in/

Slot

Booking Link

I-STEM Slot Booking link for

External User

|

Booking

available for

Internal

and External Both

Requisition

form for

Internal

External External

|

|

|

Faculty

In-charge:

Dr.

Murali KP

Email

ID:

kpmurali@nitc.ac.in

Phone

number:

0495-2286414

|

Technical

Staff:

Sanal

PR (TA SG I)

sanal@nitc.ac.in

Jithin

Krishna M (TA)

jithinkrishnam@nitc.ac.in

Jijeesh

k (ST)

jijeeshk@nitc.ac.in

|

Department-

MED

Office

Email ID

medoffice@nitc.ac.in

Location

Material

Science Lab Production Block

Lab

Phone No

0495-2286450

|

|

|

|

|

|

|

|

|

Bottom pouring type stir casting machine

Supports Aluminium and Magnesium stir casting processes.

Partial Argon atmosphere control for Al, full SF6 + Ar control for Mg.

Motorized stirrer with variable speed up to 1500 RPM and interchangeable

blades.

Max furnace temperature of 1000°C with capacities of 2, 5, 10, and 50 kg.

PID-based temperature control with ±2°C accuracy and dual thermocouples.

Gas-shielded bottom pouring prevents oxidation during Mg casting.

Pre-heating furnace for nano/alloy particles up to 800°C (Al) and 500°C (Mg).

Integrated control panel and gas mixing chamber (for Mg models).

Fully assembled on a mobile frame with safety and convenience features.

Vacuum casting

·

Pump: single

or two stage

pump

·

Gauge: Analog

dial type

·

Control: Using

electric solenoid valve

·

Max. Vacuum: 760 mmHg

Squeeze Casting

·

Maximum pressure of hydraulic power

pack: 100 tons Maximum pressure of hydraulic power

pack: 100 tons

·

Maximum load that can be applied

on the die: 50 tons

·

Control: Digital indication & control

·

Pathway heater

max. temp: 450 0C

·

Pathway heater

temp. control: PID based ON/ OFF controller with K type sensor

·

Die: Mild steel (water

cooled die available under additional cost)

·

Safe load

conditions: 40 tons for Aluminium and 10 tons for Magnesium

|

·

Sample Type: Al

and Mg alloys

·

Type of

Samples to be Analysed - Metallic

·

Maximum No.

of Samples Accepted at a Time- 1

·

Minimum No of

Days Required for Analysis – 2 Days

|

|

Internal

|

External Academic Institutes

|

National R&D Lab

|

Industry

|

|

1000/- per sample

|

2000/- per sample +

GST

|

2000/- per sample +

GST

|

2000/- per sample +

GST

|

|